MRCM News / 2017-07-22 / Hits(4862)

For grinding, the grinding debris is very small, and in the grinding process will produce a lot of heat, so the choice of cutting fluid to consider both the lubrication and cooling performance, but also consider the filter fluid filter. If the choice of cutting fluid viscosity is too large, the chip can not be deposited in time or filtered out, then the cutting fluid will be recycled to the processing area and scratch the surface of the workpiece, thus affecting the processing surface finish.

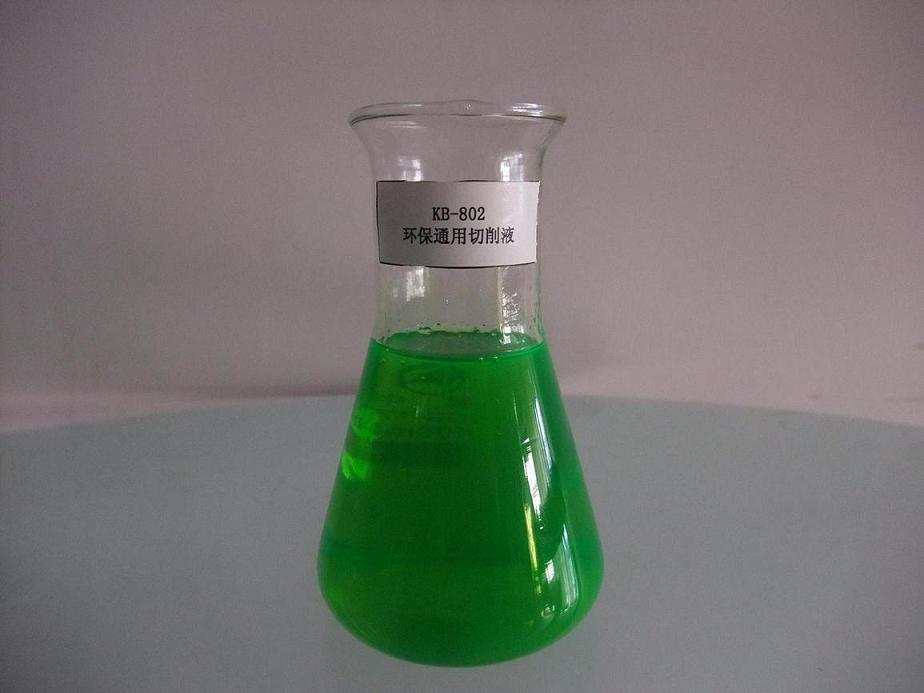

In addition to the choice of cutting fluid, in addition to consider the cutting fluid lubrication, cooling and other properties, but also to consider the cutting fluid rust, cost and easy maintenance and other aspects of performance. Cutting oil easy to use viscosity is relatively low base oil by adding anti-friction additives, so that both can achieve lubrication friction, can also have a good cooling and easy to filter. However, the problem of cutting oil is that the flash point is low, the smoke is heavy at high speed cutting, the risk coefficient is high, and the volatilization is fast and the user's use cost becomes higher. Therefore, when the conditions permit, try to use water-soluble cutting fluid.

For water-based cutting fluid, it is more important to consider its anti-rust. Now commonly used water-based aluminum rust inhibitor silicate and phosphate, for the process between the longer storage of the workpiece, easy to use in the processing with phosphoric acid type rust inhibitor cutting fluid, because the silicon material and aluminum long Time contact will produce corrosion to produce black "silicon spot". The pH value of the cutting fluid is kept at 8 to 10, and if the rust resistance is not good, the aluminum material is easily corroded under this basic condition. Therefore, the water-soluble cutting fluid must have a good aluminum anti-rust performance.

TAIZHOU MEIRI NEW ENERGY CO., LTD. is a manufacturer that specialized in developing and producing small special-purpose tool grinders, precision machinery tools. Main

products include: drill bit sharpener, end mill sharpener, screw tap sharpener, lathe tool grinder, saw blade sharpener, universal cutter grinder, universal tool grinder,

chamfer, tapping machine, gear chamfering machine, universal head, rotary table, etc.

“MRCM do NOT have any MOQ requirement. We can send a sample model to you for quality check and test within 72hours. It's ALL FREE ! ”